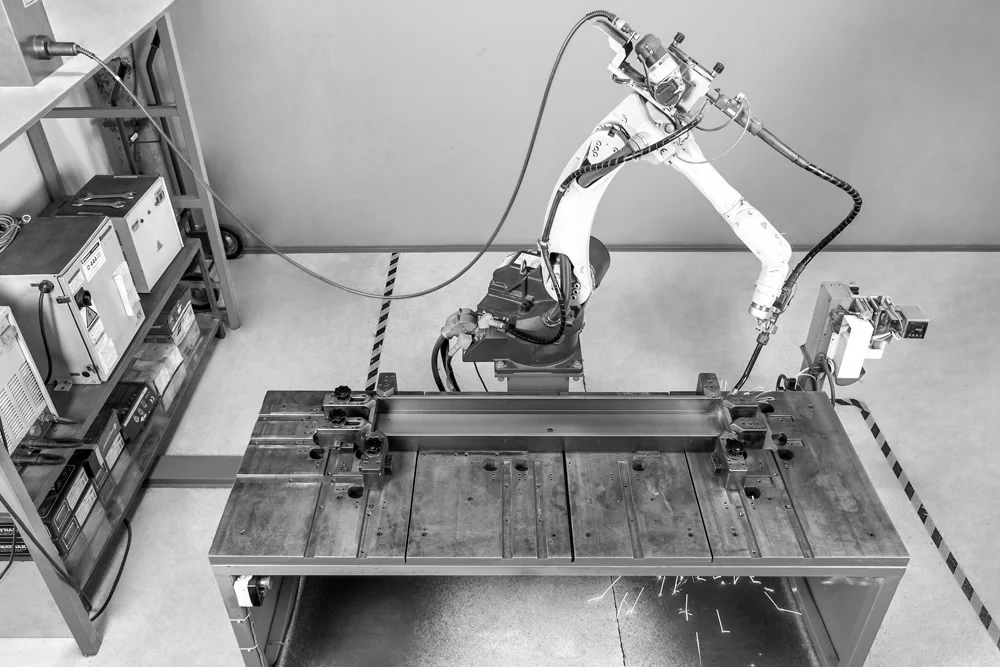

Welding

Spot welding for indoor products and 6-axis welding robots for sustainable quality of IP protection.

The use of robotic technology allows for precise and quick results, less waste, and greater safety. The robots are capable of reaching otherwise inaccessible locations and can perform complicated and precise weld lines and welds more quickly than in manual welding. This frees time for manufacturing and allows for more flexibility.

Welding robots with integrated torch cable system. Arc sensors detect deviation of welding current.

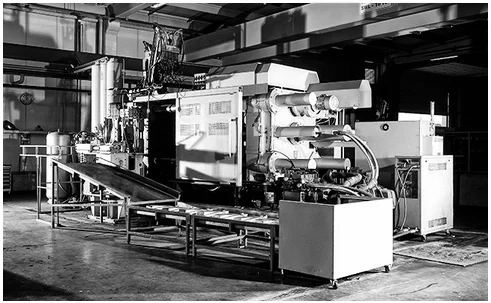

Die- cast Aluminium Injection Unit

5 machines starting from 420 tons up to 1250 tons with a total capacity of 3650 tones.

Full automated and robot integrated machines with auto ladler, auto extractor and auto sprayer to ensure process quality and endurance of the die-cast parts.

By the help of this technology products have extended life time and higher IK rating compared to other housing raw materials.

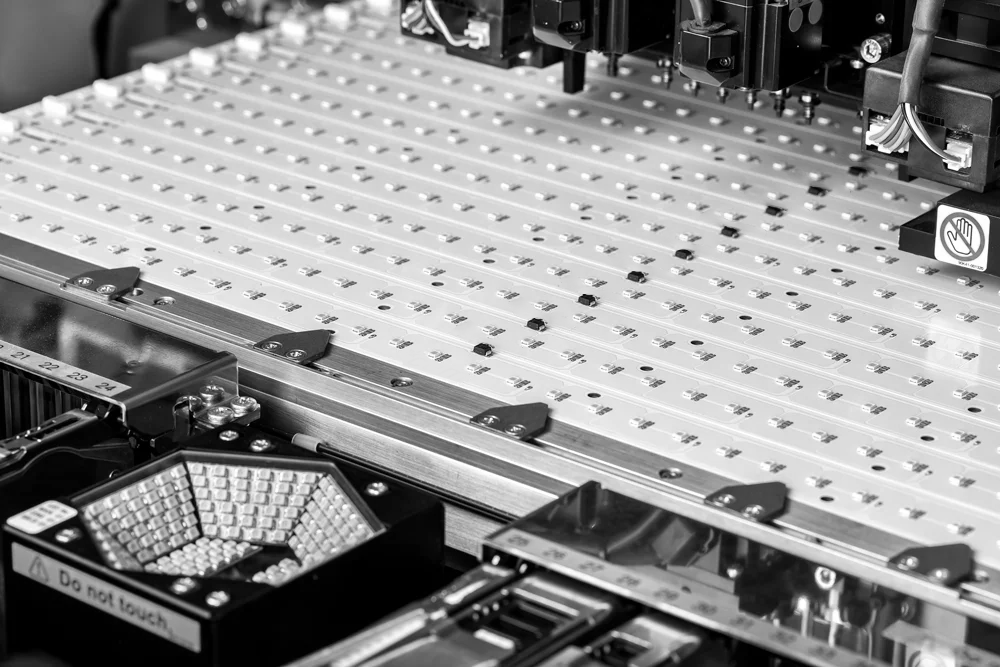

Metal Processing

A full production unit for sheet metal housings and reflector production.

Punching /Bending /Shearing

Eccentric press capacity 720 tons

Hydraulic press capacity 1388 tons

Lamination press capacity 185 tons

Pneumatic press machines and asymmetrical plate roller machines.

Surface Treatment Unit

3 shot-blasting units for die-cast parts to have a better surface and preparation before powder painting unit.

Foam Gasket Unit

3 units for dynamic sealing, casting and bonding with robots.

Usage of silicon or polyurethane raw materials on the base of application of the luminaire for indoor or outdoor.